Custom Manufacturing Solutions - From Concept to Installation

23,000 sq ft precision facility in Woodland, CA • Serving clients worldwide since 1973

Whether you need specialized agricultural equipment, precision machining, or custom fabrication, AIM delivers integrated solutions that other companies can't match. Our full-service approach means seamless coordination from initial concept through final installation—eliminating the hassles of working with multiple vendors.

From our comprehensive machine shop equipped with lathes and precision mills to our advanced pre-fabrication facility featuring plasma and waterjet cutting capabilities, we maintain complete control over quality and timelines. This integration allows us to solve complex manufacturing challenges that require both innovative engineering and skilled craftsmanship—whether you're processing nuts for global distribution or developing custom industrial systems.

When you partner with AIM, you're not just buying equipment—you're gaining access to decades of specialized knowledge, complete manufacturing control, and a team dedicated to your success. It's why industry leaders choose us again and again for their most demanding projects.

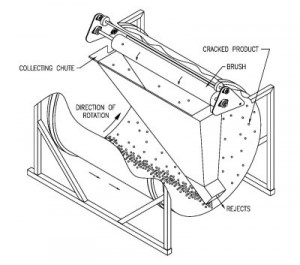

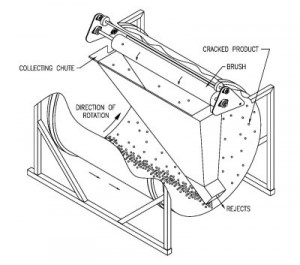

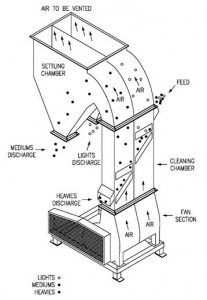

From pistachio processors removing open shells to walnut facilities eliminating damaged nuts, our Pinsorters operate 24 hours a day with needle sheets that last years, not months. It's this kind of specialized engineering that has made AIM the go-to manufacturer for agricultural operations worldwide.

A wide variety of Pinsorter liner sheets and needle sheets are typically in stock!